Our client is a significant global manufacturer of electronic components for electromobility, protective modular systems, and intelligent transport systems. They decided to establish the production of new key components within the European market.

Service

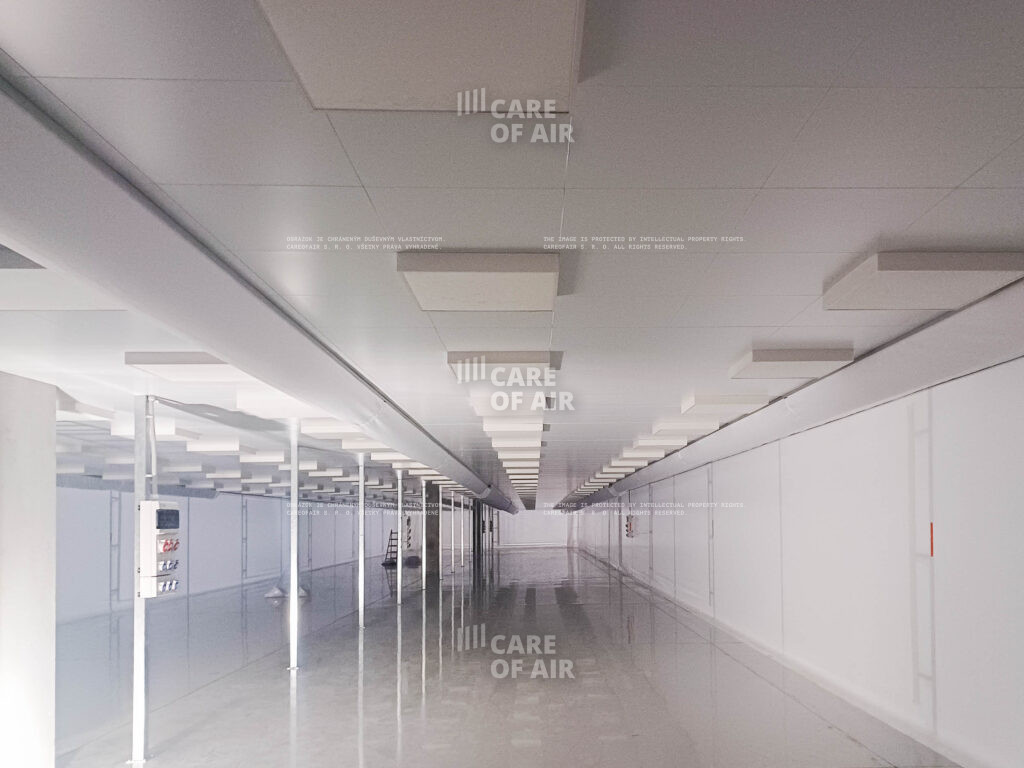

We designed and built a temporary modular cleanroom of cleanliness class ISO 8 and ESD (Electrostatic Discharge) design within one month. The cleanroom is available for rental immediately, and we will fully arrange technological modifications according to the client’s criteria.

Our client required the design and subsequent construction of temporary cleanrooms for the production of prototype components in cleanliness class ISO 8 and ESD design. A critical requirement was the speed of construction—the client had only one month for this process, and after completing the prototype production, they needed to immediately dismantle and remove this temporary cleanroom from the production hall.

Throughout the entire period, the construction of the future permanent cleanroom was taking place in the production hall, which the implementation of the temporary cleanroom could not restrict. We monitored the cleanroom construction daily, coordinated all subcontractors, and supervised the quality of the work performed. Given that this cleanroom is a temporary solution, we used high-quality ESD fabric for cladding and a cassette ceiling suitable for cleanrooms. We separated the personnel airlock with antistatic hanging lamellas and equipped it with an ESD grounding tester for entering personnel. We also created the second entrance to the tent for service purposes, allowing for the entry of oversized client technology.

HVAC System

We implemented the HVAC system by drawing air from the hall space via exchange units. Proficient air purifiers with HEPA filters handle the filtration, which blows filtered air into distribution ducts along the whole temporary cleanroom. As the client requested, the exchange units regulate heating and cooling. HVAC technologies have specific placements that consider statics and spatial possibilities.

Monitoring Parameters

The client has a control system with a 7-inch touch display for setting space parameters and monitoring the status and temperature in the cleanroom. The technicians were trained to use the system comprehensibly, and with remote access, CARE OF AIR technicians can also monitor the room.

The cleanroom’s handover to the client was preceded by its validation and professional training on the relevant technologies.

Service During Rental

Throughout the rental period, we are available to the client 24/7. We conduct weekly visits to check the rooms’ technical factors and the condition of all stages of pre-filtration. The client focuses on production and does not need to be burdened with maintaining the cleanroom’s operational aspects. The purchase and installation of ESD furniture in these cleanrooms complemented the comprehensiveness of our services.

Advantages of Temporary Cleanrooms

Temporary cleanrooms help clients quickly respond to their customers’ demands. They create a functional production environment in the required cleanliness class and optimize the financial costs needed for a new production process. Thanks to a reliable partner in the field of cleanroom construction, they gain a significant advantage over their competition. While competitors are still addressing the adjustment or construction of a new cleanroom for their production segment, our clients are already producing and fine-tuning the quality parameters of their internal processes.